High-efficiency Wastewater Purifier

Category

零售价

市场价

重量

库存

隐藏域元素占位

- Overview

-

- Commodity name: High-efficiency Wastewater Purifier

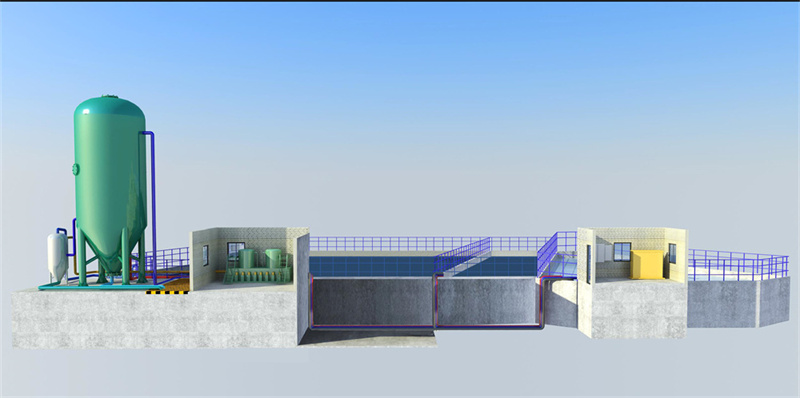

In the treatment of sewage with high suspended solids (SS), the HPO-XL High-Efficiency Sewage Purifier demonstrates significant technical advantages. It eliminates the need for a pre-sedimentation tank and can continuously purify sewage with SS ≤ 5000mg/L to 5~30mg/L efficiently and rapidly. This technology can handle sewage with SS up to 10000mg/L, opening up a new path for the treatment of high-concentration coal-containing sewage, ash slag water, mine sewage, sand and gravel aggregate washing sewage, construction sewage, and sewage with high suspended solids.

1. Overview

In the treatment of sewage with high suspended solids (SS), the HPO-XL High-Efficiency Sewage Purifier demonstrates significant technical advantages. It eliminates the need for a pre-sedimentation tank and can continuously purify sewage with SS ≤ 5000mg/L to 5~30mg/L efficiently and rapidly. This technology can handle sewage with SS up to 10000mg/L, opening up a new path for the treatment of high-concentration coal-containing sewage, ash slag water, mine sewage, sand and gravel aggregate washing sewage, construction sewage, and sewage with high suspended solids.

2. Application Scope

- Suitable for the treatment and reuse of coal-containing sewage, ash slag water, mine sewage, sand and gravel aggregate washing sewage, and construction sewage;

- Suitable for waterworks in towns and industrial and mining enterprises that use rivers, lakes, reservoirs, etc., with water turbidity less than 3000mg/L as water sources, serving as the main water purification device;

- Possesses special adaptability to lake water sources with low temperature, low turbidity, and seasonal algae;

- Used in circulating water systems in the metallurgical industry, which can effectively and significantly improve the quality of circulating water.

3. Main Features

- Through high and new technology, this process organically integrates centrifugal separation, gravity separation, solid-liquid separation, dynamic barrier filtration, and sludge thickening into one. It completes multi-stage purification of wastewater in the same tank, realizing on-line rapid, continuous, and efficient treatment.

- High treatment efficiency (the wastewater purification time is generally only 20-30 minutes depending on the SS concentration, and the purified water can be reused or discharged).

- Small floor area (only 1/8-1/10 of the traditional process; for example, a single equipment with a wastewater treatment capacity of 100m³/h only covers an area of 9m²).

- Rapid sludge thickening (the sludge discharged from the underflow of the equipment is easy to dewater and dry quickly, and is suitable for various drying equipment and natural drying ponds/sites).

- Low power consumption and low operating cost; it can operate according to peak and off-peak water volumes respectively.

- Short process route, stable and reliable operation, and simple management and operation (only one person is required to manage it per shift, and automatic control can also be implemented).

- High degree of automation: it can complete automatic operations of chemical dosing, purification, backwashing, and sludge discharge, realizing unattended operation.

- Adopts dynamic barrier filtration technology with low filtration load, high filtration efficiency, and long backwashing cycle. Special backwashing technology is used to prevent filter layer hardening.

- Low investment cost (70% lower than the price of similar advanced foreign products).

- Good treatment effect: the SS of the treated effluent can reach 3~30mg/L, and the COD removal rate can reach 40-99.9%. The treated water can be reused to achieve "zero discharge".

4. Working Principle and Structure

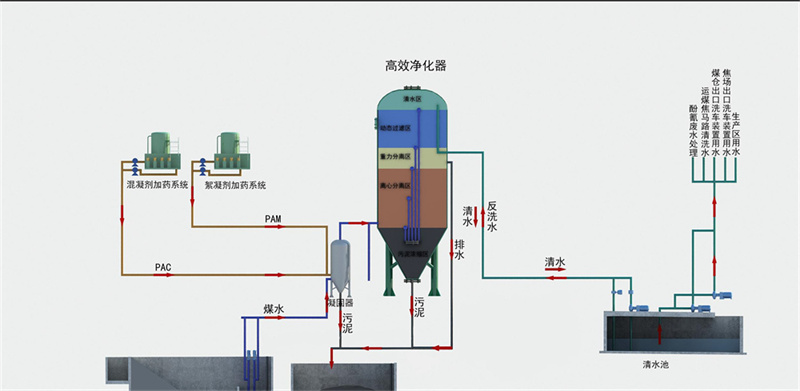

The HPO-XL High-Efficiency Sewage Purifier is improved on the basis of the original HPO High-Efficiency Sewage Purifier. It organically integrates physical and chemical reactions, and integrates direct-flow coagulation, critical flocculation, centrifugal separation, sludge dense layer contact filtration, high-efficiency clarification, variable-pore filtration, and sludge thickening and sedimentation technologies. It is an integrated combined equipment that completes rapid multi-stage purification of wastewater in the same tank within a short time (25~30min). The SS removal rate of this equipment is as high as 99.9%, and the COD removal rate reaches 40%~70%.

The purifier is a steel tank, with a cylindrical upper-middle part and a conical lower part. From bottom to top, it is divided into a sludge thickening area, a coagulation area, a centrifugal separation area, a sludge dense layer contact filtration area, a high-efficiency clarification area, a filtration area, and a clear water area. Direct-flow coagulation and critical flocculation technologies replace the coagulation reaction tank. Flocculants and coagulant aids are added before and after the pump, and the hydrolysis, mixing, double-layer compression, and adsorption-neutralization of the chemicals are completed by the pump, pipeline, and water flow. Then, the mixture enters the tank at high speed along the tangential direction to quickly complete adsorption bridging and flocculation to form flocs.

Direct-Flow Coagulation and Micro-Flocculation Mechanism

During the sewage purification process, coagulants and coagulant aids need to be added according to the water quality and requirements. Through the hydrolysis of the coagulant, Al³⁺, Fe³⁺, H⁺, and OH⁻ are generated for electrical neutralization, which compresses the double electric layer, reduces the δ potential, destabilizes the colloid, reduces the repulsion between colloid particles, and causes the particles to collide and agglomerate. The addition of coagulant aids plays a role in adsorption bridging. The high polymers formed by the hydrolysis and polycondensation of macromolecular substances have a linear structure. Colloidal particles have a strong adsorption effect on such macromolecular substances, enabling adsorption bridging between colloidal particles, making the particles gradually larger and forming visible flocs. The coagulation reaction is generally completed within 10~30 seconds, and the flocculation time is generally completed within 4~6 seconds. Based on this principle, no coagulation reaction tank is installed before the high-efficiency cyclone.

After the sewage completes the first-stage purification and moves downward in a spiral motion to a certain extent, it moves upward in a spiral motion along the gap between the inner and outer barrel walls under the action of pressure. Under the action of centrifugal force and gravity, the sewage continues to complete solid-liquid separation. The flocs are thrown to the outer barrel wall and slide down to the sludge area, enabling the sewage to complete the second-stage purification.

Sludge Dense Layer Contact Filtration Principle

After the sewage enters the dense sludge layer at the lower part of the high-efficiency clarifier through downward spiral motion, it starts to move upward. The dense sludge layer acts as a contact medium to form a good filter layer, allowing the sewage to be filtered, lifted, and purified through the sludge layer.

High-Efficiency Clarification Principle

For the sewage filtered through the sludge dense layer contact filtration, the kinetic energy in the water is used to pass through the shallow sedimentation area from bottom to top. During the downward movement of fine particles, they will come into contact with the upward-moving particles in the water, thereby enhancing the contact and adsorption between solid particles in the water, forming good flocs, and accelerating the sedimentation speed to clarify the water.

Variable-Pore Filtration Principle

After the second-stage purification of the sewage, there are still a small amount of flocs in the sewage that fail to be separated. Therefore, a filtration area is designed, and variable-pore filtration is adopted to ensure that the final effluent of the equipment is clear, with SS ≤ 10mg/L. Variable-pore filtration is a deep-bed filter designed based on the principle of "co-directional coagulation". The flocculant added to the sewage utilizes the co-directional coagulation of suspended particles in the filter layer pores during the deep-bed filtration process, thereby increasing the possibility of small suspended particles turning into large particles and being intercepted by the filter media, thus improving the filtration efficiency and the quality of filtered water. Its main feature is the use of filter media with significantly different particle sizes, which are fully mixed during operation, forming uneven pores that extend to the entire depth of the bed layer. This is like forming numerous micro-filtration "funnels" on the filter bed layer. The larger gaps between each group are the upper ports of the funnels, and the gaps formed by the small particle sizes mixed between the large particle sizes are larger, forming the cone bottoms of the funnels. The suspended solids in the water are intercepted by these funnels. Since the pores formed between the large-particle-size filter media account for the majority, the water with impurities is guided by these pores to flow to the depth of the bed layer. Therefore, filtration occurs not only near the surface but throughout the entire bed layer.

Variable-pore filtration improves the flocculation efficiency of suspended particles, enhances the pollutant interception capacity, and reduces the filter layer resistance.

Sludge Compression and Sedimentation Mechanism

A conical sludge hopper is designed at the lower end of the high-efficiency clarifier, with a cone angle of 55~60°. There is a turbid liquid surface in the upper-middle part of the sludge hopper, and the sludge concentration is about 1~3%. Under the action of cohesion, the particle group combines into a whole, and each particle maintains a relatively fixed position and settles in layers. In the lower-middle part of the sludge hopper, the sludge concentration is relatively high, and the particles are close to each other and support each other. Under the action of water pressure in the high-efficiency clarifier, the gravity of the upper particles, centrifugal force, and structural deformation, the pore water between the particles is continuously squeezed out of the interface, the particle concentration is continuously increased, and the particles are thickened and compacted to complete compression and sedimentation. Finally, the sludge is discharged from the sewage outlet, and its concentration can reach 6~10%.

This product has passed the appraisal meeting organized by the Shandong Provincial Science and Technology Commission and the Shandong Provincial Environmental Protection Bureau, with the participation of units such as the National Science and Technology Commission, the Ministry of Geology and Mineral Resources, and the National Environmental Protection Bureau. It was rated as the "Best Practical Environmental Protection Technology" by the Shandong Provincial Environmental Protection Bureau and promoted throughout the province. At the same time, it won the Second Prize of Shandong Provincial Science and Technology Progress, the Gold Award of the National Environmental Protection Product Industry and the 6th International Environmental Protection Exhibition, and obtained the National Environmental Protection Product Certification Certificate. It was listed as the first batch of scientific and technological development plan projects in Zhucheng City in 2023.

Product Application Performance

Nearly 100 sets of this product have been promoted in wastewater treatment and reuse projects in industries such as coal, thermal power generation, papermaking, and printing and dyeing, and have been widely praised by users.

I. Product Features

The HPO High-Efficiency Cyclone Sewage Purifier is a new sewage treatment technology equipment integrating years of research results of our institute, with the following significant advantages:

- Through high-tech integration technology and special processes, this equipment organically integrates coagulation reaction, centrifugal separation, gravity separation, dynamic filtration, and sludge thickening into one, which is completed in the same tank, realizing on-line rapid, continuous, and efficient treatment.

- High treatment efficiency (the wastewater purification time is generally only 20-30 minutes depending on the SS concentration, and the purified water can be reused or discharged).

- Small floor area (only 1/6 of the traditional process; for example, a single equipment with a wastewater treatment capacity of 100m³/h only covers an area of 9m²).

- Rapid sludge thickening (the sludge discharged from the underflow of the equipment is easy to dewater and dry quickly, and is suitable for various drying equipment and natural drying ponds/sites).

- Low equipment maintenance (no rotating parts inside the equipment), and the equipment basically requires no maintenance.

- Low power consumption and low operating cost (only one lifting is required during operation, and the chemical cost for wastewater treatment is about 0.06-0.20 yuan per ton of wastewater).

- Short process route, stable and reliable operation, and simple management and operation (only one person is required to manage it per shift, and automatic control can also be implemented).

- Convenient backwashing. The backwashing water can use the purified water treated by the purifier. Due to the adoption of special process treatment, the backwashing cycle can reach 3-4 times a month, and each backwashing time is only 3-5 minutes.

- The interior of the purifier uses special filter media (foam filter beads) with high strength and large adsorption surface area. Surface adsorption is adopted, which is not easy to block, the adsorbate is easy to fall off, the filter media has no loss, and no replacement is required.

- Low investment cost (70% lower than the price of similar advanced foreign products).

- Wide application range (suitable for various wastewater qualities with low and high suspended solids).

II. Working Principle

Wastewater enters the regulating tank and is pumped to the purifier by the inlet pump. At the same time, using the negative pressure principle, the chemicals and wastewater are sucked into the pipeline together for preliminary mixing and then enter the purifier. In the purifier, through processes such as coagulation reaction, centrifugal separation, gravity separation, dynamic filtration, and sludge thickening, the purified water is discharged from the top of the purifier, and the thickened sludge is discharged regularly or continuously from the bottom. After operating for a period of time, the backwash pump is turned on for backwashing. This product replaces the cumbersome process flow and structure system of traditional stirred coagulation reaction, sedimentation, sludge scraping, lifting, filtration, backwashing, and sludge thickening.

Keywords:

Messages

-

-

-

Wastewater treatment experiment results