News details

Detailed explanation of the SBR wastewater treatment process.

Release time:

2024-04-26 08:29

SBR is the abbreviation of sequential batch activated sludge method, also known as intermittent activated sludge method, which is an activated sludge process operated by intermittent aeration method.

Compared with other processes, it only takes one pool to change to different reaction stages in chronological order.

The work process is divided into water inlet stage, reaction stage, precipitation stage, closed water stage and standby stage.

Step 1: From the beginning of water intake to the end of the maximum volume of the equipment.

Step 2: According to the growth characteristics of different microorganisms, the nature of the sewage and the treatment effect to achieve, it can be operated by non-restricted aeration, semi-limited aeration, and limited aeration. By controlling the dissolved oxygen of the sewage in the reaction chamber, it can achieve anaerobic, hypoxia and aerobic reaction environment, and complete a variety of treatment functions. In order to achieve the purpose of removing organic matter, and the effect of nitrogen removal and phosphorus removal can be achieved.

Step 3: The purpose of the sedimentation stage is to carry out solid-liquid separation, which is equivalent to the precipitation time of the second sedimentation tank, which is usually set to 1-1.5 hours until the sludge floc and the supernatant are separated.

Fourth cloth: The closed water stage is to discharge the supernatant by using a decanter in the reactor until the lowest water level.

The next water intake is in the standby stage, and excess sludge can be discharged at this stage.

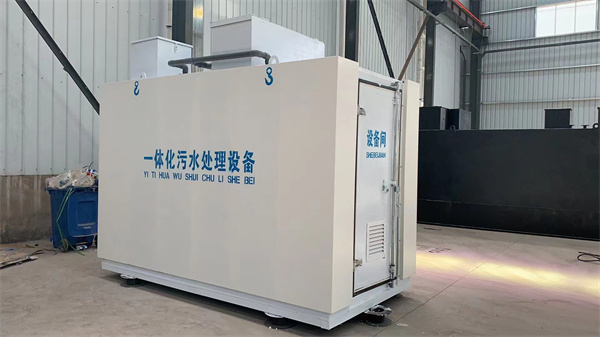

The equipment has the advantages of small footprint, simple structure, low investment, low operating cost, and high nitrogen and phosphorus removal effect.

Detailed explanation of the SBR wastewater treatment process.

Related news

Contact: +86 18016210178 (Ms.Liu)

Add:No.56, Donghuan Road, Zhucheng City, Weifang City, Shandong Province