Plate and frame filter press

Category

零售价

市场价

重量

库存

隐藏域元素占位

- Overview

-

- Commodity name: Plate and frame filter press

Plate and frame filter press is an intermittent pressurized filtration device used for solid-liquid separation of various suspensions. It relies on a compression device to tighten the filter plate, and then uses a material pump to press the suspension into the filter chamber, achieving the purpose of separating solid particles and liquid materials through a filter cloth.

What is the plate and frame type sludge filter press?

Plate and frame type sludge filter press is an intermittent solid-liquid separation equipment, which is composed of puzzle plates and filter frames arranged to form a filter chamber. Under the pressure of the feed pump, the feed liquid is sent into each filter chamber, and the solid and liquid are separated through the filtering medium. Widely used in chemical, dye, petroleum, ceramics, pharmaceuticals, sugar making, food, starch, Yitang, paint, metallurgy, and sewage treatment in various industries. It has advantages such as good separation effect, wide application range, simple operation, and low investment, especially for the separation of sticky and fine materials, which has incomparable advantages.

Application Range of the Plate and Frame Filter Press

Plate and frame filter press is an intermittent pressurized filtration device used for solid-liquid separation of various suspensions. It relies on a compression device to tighten the filter plate, and then uses a material pump to press the suspension into the filter chamber, achieving the purpose of separating solid particles and liquid materials through a filter cloth. The complete machine has a simple structure, good separation effect, convenient use, and a wide range of applications. It is widely used in fields such as coal washing, inorganic salts, mining, alcohol, petroleum, chemical industry, dyes, metallurgy, medicine, textile, printing and dyeing, papermaking, and sewage treatment.

Working Principle

(1) The filter press is composed of a frame, a filter plate, a pressing system (in three forms: manual, mechanical, and hydraulic), and an electrical control cabinet.

(2) The rack part serves as a support for the compression device and filter plate, and is composed of the base, push plate, tail plate, and main beam.

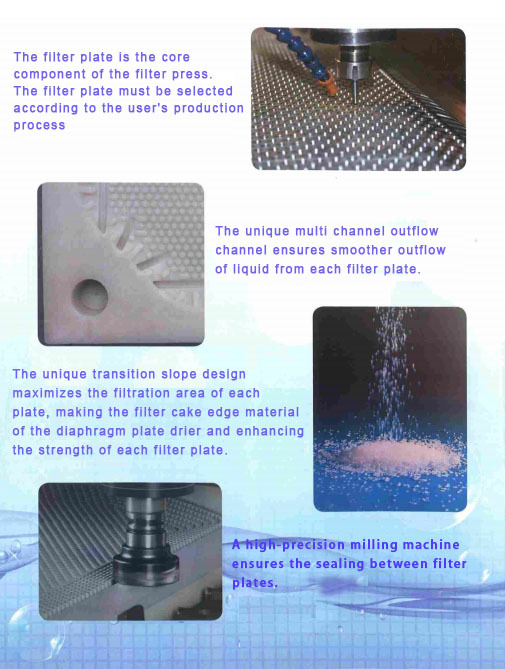

(3) The filter plate is installed on the main beam between the tail plate and the push plate, with filter cloth sandwiched between them.

(4) During operation, the push plate is pushed by a compression device (oil cylinder piston rod or screw), which compresses the filter plate and filter cloth located between the push plate and the tail plate. A filter chamber is formed between the compressed filter newspaper and the filter plate. The material pumped in by the material pump enters each filter chamber from the feed hole of the tail plate, and solid particles are trapped in the filter chamber, forming a filter cake. The liquid is discharged from the machine body through the filter cake and filter cloth through the outlet hole. If it is necessary to wash the filter cake. The filter cake can be washed with washing water through the washing solution port on the tailboard

5.If it is necessary to blow dry the filter cake, compressed air can be introduced through the washing solution port to blow dry the filter cake. (5) The structure of the plate and frame type filter press frame is the same as that of the box type filter press frame, except that the filtering part is composed of filter cloth plates and frames, and the plate and frame space is the filter chamber.

(6) The liquid flow form of the filter press is divided into open flow and dark flow. Open flow refers to the direct discharge of filtrate from the outlet hole of each filter plate outside the machine; Underflow refers to the collection of filtrate from various filter plates and discharge from the machine through the outlet channe

Structure and principle of the Filter Press

Some SPEC of the Sludge of Filter Press

Filter Press Photos Display and Customer Cases

Keywords:

Messages

Contact: +86 18016210178 (Ms.Liu)

Add:No.56, Donghuan Road, Zhucheng City, Weifang City, Shandong Province