- Overview

-

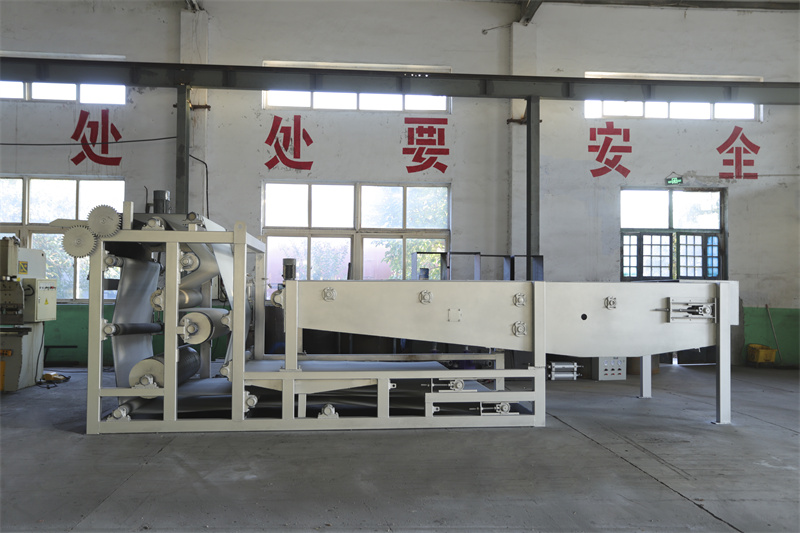

- Commodity name: Mine Sludge Treatment Equipment

I. Introduction to Tailings Slurry Treatment Equipment:

All dewatering discs and feed hoppers of the tailings slurry treatment equipment are made of stainless steel, featuring strong corrosion resistance. The machine operates continuously, with an extended gravity dewatering section and a reverse rotation mechanism, which ensures excellent dewatering effect and significantly improves processing capacity. The tailings slurry treatment equipment can add different flocculants according to sludge properties and incoming sludge volume, freely adjust the filter belt tension and moving speed, and is equipped with an automatic deviation correction device for the filter belt.

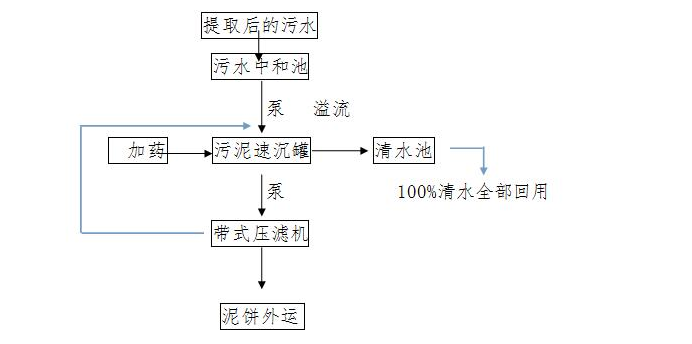

II. Process Flow of Tailings Slurry Treatment Equipment:

A pipeline mixer and sludge distributor are installed at the inlet of the tailings slurry treatment equipment. After fully mixing the sludge with flocculants, the mixture is evenly and gently distributed on the horizontal section of the upper filter belt for gravity dewatering. To quickly drain the free water in the sludge, the following four measures are adopted:

(1) An open filter belt support frame is installed under the horizontal sections of the upper and lower filter belts, which helps break the tension of water in the filter belt pores, enabling the filtrate to be effectively discharged through each filter hole.

(2) Sludge turning plows: Multiple sets of sludge turning plows are arranged on the horizontal section of the upper filter belt, installed in a staggered front-to-back manner. They can continuously turn the sludge from one side to the other to increase the contact opportunity between the sludge and the filter belt, accelerating the discharge of free water.

(3) Sludge flipping: The sludge at the end of the upper filter belt gently falls onto another clean lower filter belt running in the opposite direction, allowing the upper surface of the sludge to come into contact with the filter belt, thereby improving dewatering efficiency.

(4) Proper selection of filter belts and gravity dewatering area: The filter belt pores and weaving method are reasonably selected after sludge dewatering tests to ensure dewatering effect. The gravity dewatering area is the key to the dewatering capacity of the tailings slurry treatment equipment; the larger the gravity dewatering area, the higher the dewatering efficiency.III. Working Principle of Tailings Slurry Treatment Equipment:

According to the different pressures in the dewatering zones, the entire dewatering process can be divided into three parts: the mesh pre-dewatering zone, the pressure dewatering zone, and the pressurized forced dewatering zone.The slurry is evenly distributed in the upper mesh pre-dewatering zone through the slurry distributor and then enters the gravity dewatering zone. In this zone, the sludge removes most of the water mainly by its own gravity, making the slurry lose fluidity, and the dewatering concentration is increased to 3%-5%. Then, it continues to dewater on the middle mesh, and the slurry enters the wedge-shaped intersection zone formed by the middle and lower meshes, namely the pressure dewatering zone. In this zone, the slurry is slightly squeezed by the middle and lower meshes, and the water is removed to about 15%-20%, then enters the pressurized dewatering zone. The pressurized dewatering zone consists of dewatering rolls with different diameters, enabling the two sides of the filter mesh to quickly dewater during extrusion. The arrangement of dewatering rolls with diameters gradually decreasing from large to small and the change of the filter mesh wrap angle ensure the formation of continuously increasing dewatering pressure and corresponding shear force, making the slurry repeatedly deform in the dewatering zone and continuously remove water until the concentration reaches more than 28% to form a mud cake, which is scraped off by the sludge scraper. The filter mesh after removing the slurry is cleaned by high-pressure water flushing and then enters the next working cycle.

IV. Advantages of Tailings Slurry Treatment Equipment:

1.The full purification of slurry is conducive to controlling the performance indicators of slurry, preventing stuck drill accidents, and improving hole formation quality.

2.The effective separation of dregs is beneficial to improving hole formation efficiency.

3.The reuse of slurry helps save slurry-making materials and reduce construction costs.

4.The closed circulation of slurry and the low moisture content of dregs are beneficial to reducing pollution.5.The use of double-layer screens improves the purification effect by nearly 50% compared with single-layer screens, with convenient and simple operation and reliable operation.

Keywords:

Messages

Contact: +86 18016210178 (Ms.Liu)

Add:No.56, Donghuan Road, Zhucheng City, Weifang City, Shandong Province