News details

A comprehensive guide to wastewater treatment equipment selection, application, and operation and maintenance, helping wastewater achieve discharge standards.

Release time:

2025-11-25 15:02

Against the backdrop of increasingly stringent environmental protection policies and the prominent issue of water scarcity, sewage treatment equipment has become an indispensable core environmental protection facility in industrial production, municipal construction, and civil livelihood sectors. High-quality sewage treatment equipment not only effectively purifies various types of sewage and reduces the environmental impact of pollutant emissions but also enables the recycling of water resources, helping enterprises lower water consumption costs and enhance their environmental compliance capabilities. This article will comprehensively analyze the core knowledge of sewage treatment equipment from dimensions such as equipment types, selection techniques, application scenarios, and operation and maintenance key points, providing professional references for industry practitioners and purchasers.

I. Core Types of Sewage Treatment Equipment and Their Applicable Scenarios

Sewage treatment equipment can be divided into multiple types based on treatment processes, treatment scales, and application scenarios, with significant differences in functions and applicable scopes among different types of equipment.

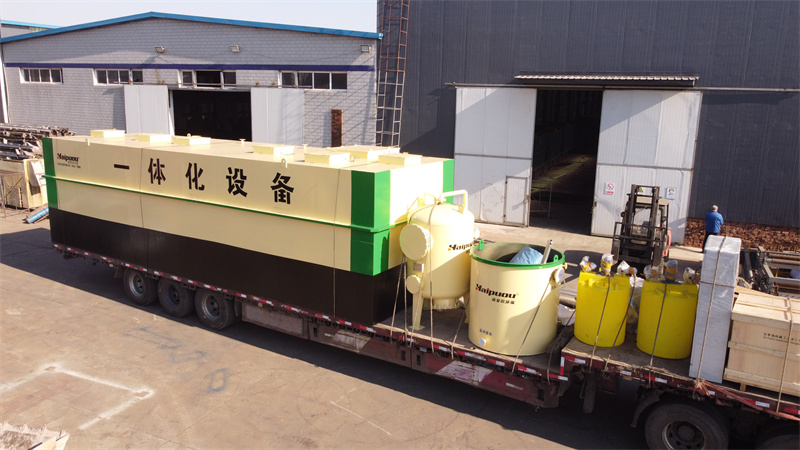

- Integrated Sewage Treatment Equipment: Adopting a modular design, it integrates multiple treatment units such as grilles, sedimentation tanks, biochemical reaction tanks, and disinfection tanks. It features a small footprint, convenient installation, and high automation. Suitable for scenarios with small sewage discharge volumes and limited space, such as small and medium-sized enterprises, township health centers, and rural communities, it can treat domestic sewage, catering sewage, and low-concentration industrial wastewater.

- Specialized Industrial Sewage Treatment Equipment: Designed to address the characteristics of industrial wastewater, such as complex composition, high pollutant concentration, and strong toxicity, it includes anaerobic reactors, MBR (Membrane Bioreactor) systems, SBR (Sequencing Batch Reactor) systems, and advanced oxidation equipment. Industries such as chemical engineering, printing and dyeing, electroplating, and papermaking can customize exclusive equipment according to the quality of wastewater (e.g., containing heavy metals, high COD, high ammonia nitrogen) to ensure that sewage meets discharge standards.

- Municipal Sewage Treatment Equipment: Mainly used in urban domestic sewage and large-scale centralized industrial sewage treatment plants. Core equipment includes grille machines, sludge scrapers, aeration equipment, and sludge dewatering machines. This type of equipment is characterized by large treatment scale, high treatment efficiency, and strong stability. It can achieve primary, secondary, or even advanced treatment of sewage, and the effluent can meet the standards for reclaimed water reuse.

- Small-sized Domestic/Commercial Sewage Treatment Equipment: Such as small septic tanks, kitchen sewage processors, and balcony sewage purification devices. Suitable for scenarios like households, catering stores, and small office buildings, it mainly solves the problem of preliminary local sewage treatment and reduces the pressure of subsequent centralized treatment.

II. Key Principles and Techniques for Selecting Sewage Treatment Equipment

The rationality of equipment selection directly affects the sewage treatment effect, operation cost, and equipment service life, requiring comprehensive consideration of multiple factors.

- Select Based on Sewage Quality and Treatment Standards: First, conduct water quality testing to identify the types of pollutants (e.g., suspended solids, organic matter, heavy metals), their concentrations, and changes in water volume. Then, select equipment with corresponding treatment processes according to the discharge limits specified by local environmental protection departments (e.g., Discharge Standard of Pollutants for Municipal Wastewater Treatment Plants (GB18918-2002), industry-specific discharge standards). For example, high-concentration organic wastewater should prioritize biochemical treatment equipment, while wastewater containing heavy metals should be matched with chemical precipitation or membrane separation equipment.

- Select in Combination with Treatment Scale and Site Conditions: Small sewage discharge units (daily discharge < 500 tons) can use integrated equipment to save site and installation costs; large sewage treatment projects (daily discharge > 10,000 tons) need to adopt decentralized combined equipment to ensure treatment efficiency and stability. At the same time, factors such as the terrain of the site, load-bearing capacity, and surrounding environment should be considered to avoid the impact of equipment installation and operation on the surrounding area.

- Balance Operation Cost and Maintenance Convenience: When selecting equipment, compare operation cost indicators such as equipment energy consumption, chemical consumption, and sludge production, and prioritize energy-saving and consumption-reducing equipment (e.g., frequency conversion aeration equipment, high-efficiency sedimentation equipment). In addition, the maintenance difficulty of the equipment, the convenience of replacing vulnerable parts, and the after-sales service capability of the manufacturer should also be focused on to reduce later operation and maintenance costs and failure risks.

- Pay Attention to Equipment Material and Environmental Compliance: The equipment material should be compatible with the corrosiveness of sewage. For example, equipment used to treat acid-alkali wastewater should be made of corrosion-resistant materials such as stainless steel and glass fiber reinforced plastic to avoid equipment aging and damage. At the same time, equipment that meets national environmental certification standards should be selected to ensure no secondary pollution during equipment operation and that it can pass the acceptance of environmental protection departments.

III. Core Technologies and Development Trends of Sewage Treatment Equipment

With the continuous innovation of environmental protection technologies, the technical level of sewage treatment equipment has been continuously improved, showing a development trend of high efficiency, intelligence, and low carbon.

- Analysis of Core Treatment Technologies: Biological treatment technology remains the mainstream. Among them, the MBR Membrane Bioreactor combines membrane separation and biodegradation technologies, featuring high effluent quality and small footprint, and is widely used in high-end industrial and municipal sewage advanced treatment; advanced oxidation technologies (e.g., UV-Fenton, ozone oxidation) can rapidly degrade refractory organic matter, suitable for pretreatment or advanced treatment of high-concentration industrial wastewater; membrane separation technologies (e.g., ultrafiltration, nanofiltration, reverse osmosis) realize efficient water resource recovery, helping enterprises build "zero discharge" systems.

- Intelligent Development Trend: Modern sewage treatment equipment is gradually integrating IoT (Internet of Things), big data, and artificial intelligence technologies. Through sensors, it can real-time monitor equipment operation parameters (e.g., flow rate, pH value, dissolved oxygen concentration) and effluent quality. Combined with an intelligent control system, it can automatically adjust the operation state to achieve precise operation and maintenance, reduce labor costs, and improve equipment operation stability. Some high-end equipment also has remote monitoring and fault early warning functions, facilitating managers to grasp the equipment operation status in real time.

- Low-Carbon and Resource Utilization Upgrading: Under the guidance of the "dual carbon" goal, energy-saving sewage treatment equipment has become a research and development focus. By optimizing process design and adopting high-efficiency energy-saving components, equipment energy consumption is reduced. At the same time, resources such as sludge and biogas generated during equipment operation are fully utilized. For example, biogas produced by anaerobic digestion of sludge can be used for power generation or heating, and dewatered sludge can be used for brick making or landscaping, realizing a circular model of "sewage treatment - resource recovery - energy utilization".

IV. Core Points of Operation and Maintenance Management for Sewage Treatment Equipment

Scientific operation and maintenance management is the key to ensuring the long-term stable operation of sewage treatment equipment and guaranteeing the treatment effect, requiring the establishment of a sound operation and maintenance system.

- Daily Inspection and Maintenance: Regularly check the operation status of various equipment components (e.g., pumps, fans, valves, membrane modules), and promptly clean up debris in grilles and sedimentation tanks to avoid blockage; regularly replace vulnerable parts (e.g., seals, filter elements) and check the lubrication of equipment to ensure normal operation of components; record equipment operation parameters and effluent quality data daily to form an operation and maintenance ledger for easy traceability and analysis.

- Regular Cleaning and Disinfection: For pollution-prone components such as membrane modules and filters, regular chemical cleaning or physical cleaning is required to remove pollutant attachments and restore equipment treatment efficiency; disinfection equipment (e.g., ultraviolet disinfection devices, chlorine dioxide generators) should be regularly checked for disinfection agent reserves and equipment operation status to ensure that effluent disinfection meets standards and prevent the spread of pathogens.

- Fault Troubleshooting and Emergency Handling: Establish an equipment fault emergency plan. When equipment malfunctions such as abnormal flow, substandard effluent, or component damage occur, promptly shut down the equipment to identify the cause, quickly replace faulty components or adjust operation parameters; reserve necessary spare parts and emergency equipment to avoid sewage treatment interruption caused by faults and prevent environmental risks.

- Professional Personnel Training: Operation and maintenance personnel should have professional equipment operation and maintenance knowledge. Regular technical training should be carried out to improve their mastery of equipment structure, treatment processes, and fault handling, ensuring standardized equipment operation and reducing equipment damage or treatment effect degradation caused by human operation errors.

V. Conclusion

Sewage treatment equipment is the core support for water pollution control. The scientific nature of its selection, the advancement of its technology, and the standardization of its operation and maintenance are directly related to the sewage treatment effect and the achievement of environmental protection goals. With the continuous tightening of environmental protection policies and the continuous advancement of technology, sewage treatment equipment will develop in a more efficient, intelligent, and low-carbon direction, providing strong support for the green development of various industries.

When selecting sewage treatment equipment, enterprises and purchasers should combine their actual needs, comprehensively consider factors such as equipment type, technical level, operation cost, and after-sales service, and select suitable high-quality equipment; at the same time, strengthen equipment operation and maintenance management, give full play to the environmental protection efficiency of the equipment, and contribute to the realization of sustainable water resource utilization and high-quality ecological environment development.

Pre

Related news