- Overview

-

- Commodity name: multi-media filter

A multimedia filter consists of multiple standard high-speed sand tank units. Water passes through the internal water distributors and collectors, and by virtue of different media, it can effectively remove particulate matter and reduce turbidity. If specific filter media are installed, such as activated carbon and anthracite, it can also adsorb and remove corresponding organic substances, ions, etc.

Equipped with unique internal water distributors, collectors, and a distinctive two-way automatic backwash valve, the filter enables individual backwashing of each standard high-speed sand tank one by one during normal system operation, with a fully automatic control program. It features low water consumption for backwashing, convenient installation, and easy operation.

Working Principle

The multimedia filter features a compact structure and high automation. Its unique structure enables the effluent turbidity to be below 0.5 NTU, with an impurity filtration precision of up to 5 microns. It supports automatic backwashing, and the product not only delivers excellent performance but also has low operating costs.

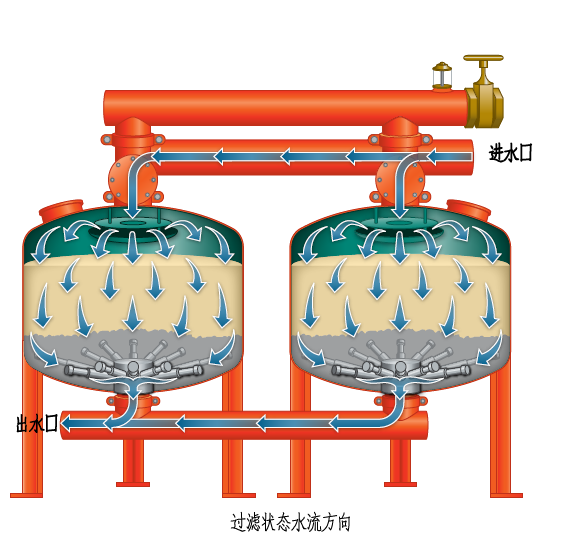

1. Normal Filtration State

When the system is in the filtration state, unfiltered water is evenly distributed by the water distributor and flows through the filler layer (refined uniform-grain quartz sand, garnet) inside the filter in a laminar flow pattern. As the water passes through the filler layer, impurities are trapped within the layer. There are multiple evenly distributed water collectors at the bottom of the filter, which uniformly collect and discharge the filtered water. The advection filtration design allows the filter to operate at high flow rates while still achieving good filtration results.

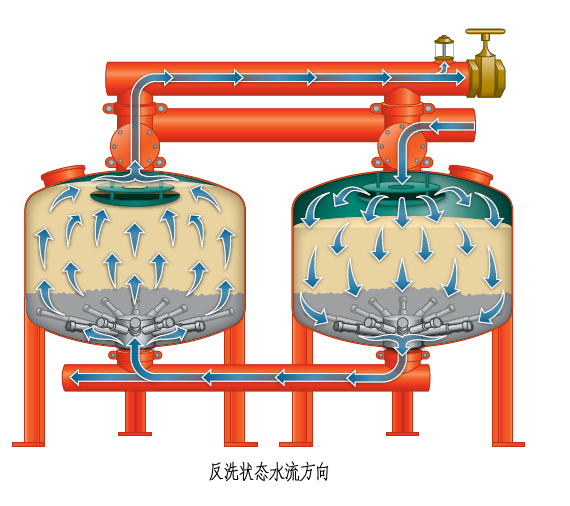

2. Backwashing State

As impurities continue to accumulate in the filler layer, the internal head loss will increase progressively. When the inlet-outlet head loss reaches a predetermined value, the system will automatically activate the pressure-setting device to switch to the backwashing state. After the backwashing of one unit is completed, the hydraulic valve changes the water supply direction to realize backwashing of each unit one by one, making it easier to clean the accumulated impurities.

While the system is in the backwashing state, filtration continues. A portion of the filtered clean water is used for backwashing the standard unit sand tank, and the rest is still delivered to the user. The backwash sewage is discharged through the backwash drain port of the hydraulic valve. In the fully automatic and high-efficiency filtration system of the high-speed sand tank, the special water collector design allows the fillers to rub against each other, maximizing backwashing efficiency and reducing the required backwash water (clean water). Meanwhile, no filler loss occurs during backwashing.

The backwashing of one standard unit sand tank takes 2 minutes. After backwashing, the internal head loss of the standard unit sand tank is reduced to a reasonable range. The pressure-setting device sends a reset signal, the hydraulic valve reverts to the filtration state, and the next standard unit sand tank is ready to enter the backwashing state.

Key Technical Term Notes

- NTU (Nephelometric Turbidity Unit): A unit for measuring water turbidity, commonly used in water treatment to indicate the clarity of water.

- Head loss: The pressure loss of fluid during flow, an important indicator for judging whether the filter needs backwashing.

- Laminar flow: A smooth, layered fluid flow state with no cross-mixing between layers, which helps improve filtration efficiency in the filter.

- Hydraulic valve: A valve controlled by fluid pressure, used to switch water flow direction and realize filtration/backwashing conversion in the system.

Keywords:

Messages

Contact: +86 18016210178 (Ms.Liu)

Add:No.56, Donghuan Road, Zhucheng City, Weifang City, Shandong Province