Printing and Dyeing Wastewater Treatment

Category

零售价

市场价

重量

库存

隐藏域元素占位

- Overview

-

- Commodity name: Printing and Dyeing Wastewater Treatment

The main pollutants in dyeing wastewater are dyes and additives. Due to the use of different dyes, additives, and dyeing methods for different fiber raw materials and products, as well as the different dye uptake rates and dye concentration, the water quality of dyeing wastewater varies greatly. The color of dyeing wastewater is generally dark, with poor biodegradability, low suspended solids, high COD and BOD values, and sometimes pH above 10 (when using sulfurized or reduced dyes)

What is the Printing and Dyeing Wasterwater?

Printing and dyeing wastewater is a general term for various types of wastewater discharged during the production process of various textile printing and dyeing enterprises. It has five major characteristics: high pollutant concentration, high chromaticity, high pH value, difficult degradation, and multiple changes. This type of wastewater has a large amount of water, high content of organic pollutants, high alkalinity, and significant changes in water quality, making it one of the difficult to treat industrial wastewater.

Feature of the Printing and Dyeing Wasterwater

The wastewater from the textile printing and dyeing industry is characterized by high water consumption, high organic pollutant content, high alkalinity, and significant changes in water quality, making it one of the difficult to treat industrial wastewater. The wastewater contains dyes, slurries, additives, oil agents, acid reducers, fiber impurities, and rare organic compounds such as F machine salts. One ton of textile processing personnel consumes 100-200 tons of water, of which 80% and 90% are discharged as wastewater.

The properties of fabrics vary, and the dyes and other chemical agents used also vary. According to different printing and dyeing substances or processing processes, printing and dyeing wastewater is classified. According to printing and dyeing substances, there are cotton textile printing and dyeing wastewater, wool textile wastewater, and chemical fiber processing wastewater. According to the processing process, there are desizing wastewater, boiling wastewater, bleaching wastewater, mercerizing wastewater, dyeing wastewater, printing wastewater, etc.

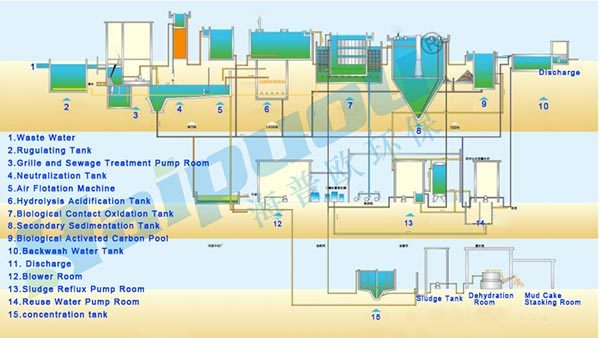

Printing and Dyeing Wastewater Treatment Process Flow (Case Study)

Reuse of Wastewater from Printing and Dyeing

The reuse of wastewater from printing and dyeing refers to the process of treating the wastewater to achieve a certain standard of water quality, and then reusing it for printing and dyeing or other industrial water. This technology can effectively reduce the discharge of wastewater, improve the efficiency of water resource utilization, and also reduce the impact on the environment.

Reuse of Wastewater from Printing and Dyeing Technology

1.Sand Filtration+UF+RO/NF processing

2.Pretreatment+RO/NF processing

3.MCR/MBR+RO/NF processing

Keywords:

Next

Messages

-

-

-

Wastewater treatment experiment results