- Overview

-

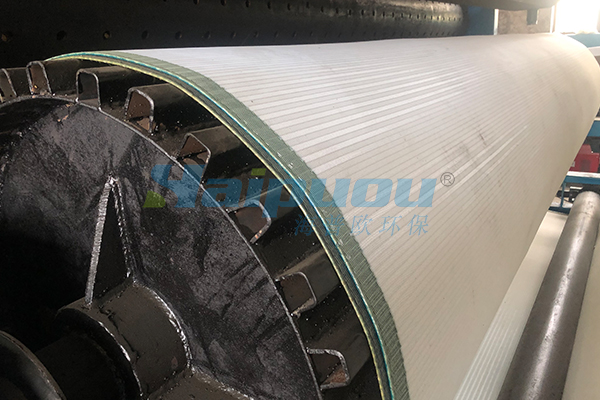

- Commodity name: Sand Washing Sewage Treatment Equipment

Product Introduction

The belt press filter is primarily composed of a drive unit, frame, press rolls, upper and lower filter belts, belt tensioning device, belt cleaning system, discharge mechanism, pneumatic control system, and electrical control system.In China's industrial landscape, challenges persist including low production concentration, weak R&D capabilities for high-end products, and outdated manufacturing technologies in the belt filter press sector, contributing to a widening trade deficit in imports and exports. The next few years will witness intensified market volatility, accelerating the polarization among brands. While consolidation will reduce the number of surviving enterprises, this transformation will also foster a more rational and competitive market environment. The localization of high-end electric components remains a critical bottleneck, with basic parts lagging behind international standards. During the 12th Five-Year Plan period, the government will continue to promote domestic production of high-end components, enabling leading enterprises to expand their presence across industries such as environmental protection, municipal engineering, mining, power generation, chemicals, electronics, food processing, pharmaceuticals, and textiles.

Structure and Function of Key Components

- Frame: Provides structural support for the press roll system and all other components.

- Press Roll System: Comprises rolls arranged in descending order of diameter. As the sludge passes between the upper and lower filter belts through these rolls, a progressive pressure gradient is applied, gradually increasing the compressive force to expel moisture.

- Gravity Dewatering Zone: Consists of a support bracket and feed chute. Here, flocculated sludge loses significant moisture through gravity, reducing its liquidity in preparation for mechanical pressing.

- Wedge Zone Dewatering Device: The converging upper and lower belts form a wedge-shaped area that applies preliminary pressure to further reduce sludge moisture and enhance consistency before entering the high-pressure zone.

- Filter Belts: The core filtration medium, where solid-liquid separation occurs. Tensioned belts wrap around the press rolls to generate the necessary compressive force for dewatering.

- Belt Tracking System: Utilizes cylinders, adjustment rollers, and sensors to maintain proper belt alignment, ensuring continuous and stable operation by correcting deviations caused by uneven tension, installation errors, or inconsistent feeding.

- Belt Cleaning System: Features spray nozzles, water collection trays, and covers to remove residual solids from the belts using high-pressure water jets, restoring filtration efficiency for subsequent cycles.

- Belt Tensioning Device: Comprising tension cylinders, rollers, and synchronization mechanisms, this system applies precise tension to the belts, critical for generating optimal pressing forces. Tension is adjustable via pneumatic controls.

- Discharge Mechanism: Includes scrapers, holders, and discharge rollers to separate the dewatered cake from the belts for collection.

- Drive System: Consists of an electric motor, reducer, and gear transmission to power the belts. Speed adjustment allows customization to process requirements.

- Pneumatic System: Comprising air tanks, pumps, cylinders, and control valves, this system provides the motive force for belt tensioning and tracking functions, ensuring precise and reliable operation.

Working Principle and Process

- Working Principle

The dewatering process involves four critical stages:

1.1 Pretreatment: Flocculated sludge is fed onto the filter belt, where gravity removes free water, reducing moisture content and increasing viscosity. Efficiency depends on filter belt properties, sludge characteristics, and flocculation quality.

1.2 Wedge Zone Pre-Pressing: After gravity dewatering, the sludge undergoes gentle compression in the wedge zone to remove surface moisture, solidifying the sludge structure to prevent extrusion during high-pressure stages.

Keywords:

Messages

Contact: +86 18016210178 (Ms.Liu)

Add:No.56, Donghuan Road, Zhucheng City, Weifang City, Shandong Province