- Overview

-

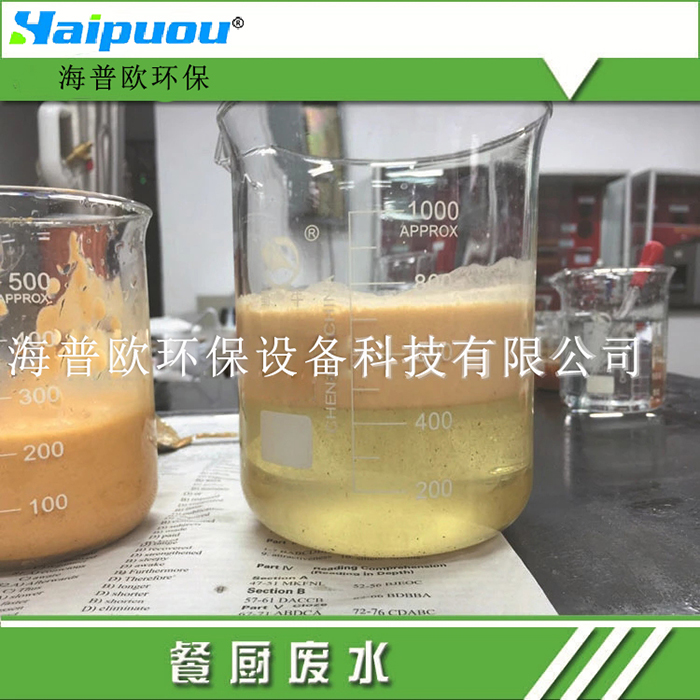

- Commodity name: Kitchen wastewater

Kitchen waste wastewater, commonly known as swill, is a type of high-concentration organic wastewater. Its water quality varies significantly depending on the type of waste, scale of the source, and season. Based on the analysis of our company's previous experience, the ratio of BOD (Biochemical Oxygen Demand) to COD (Chemical Oxygen Demand) in the incoming water is generally between 0.3 and 0.6, indicating good biodegradability. Therefore, a biological treatment process is adopted for the treatment of this type of wastewater. Given the characteristics of the wastewater—such as containing oil and having a high SS (Suspended Solids) concentration—an oil separator and air flotation are used to remove oil and SS from the wastewater, serving as pretreatment before the biochemical treatment of the sewage. The biochemical section adopts the MBR (Membrane Bioreactor) treatment process, with nitrification and denitrification facilities installed to effectively remove COD and ammonia nitrogen.

The MBR process is used for kitchen waste wastewater treatment. Due to its high sludge concentration, the volume of treatment structures is significantly reduced, resulting in low project investment, stable treatment effects, and high cost-effectiveness.

Comprehensive Regulation Tank

Kitchen waste wastewater contains a large amount of suspended solids and oil. To ensure the normal operation of subsequent treatment processes, it is necessary to filter out the oil and suspended solids from the wastewater. Therefore, before entering the MBR treatment system, the wastewater first flows into a cyclone oil separator, and then into an air flotation tank to remove oil and large-particle substances from the sewage.

Air Flotation Tank

During the upward flow of the sewage, it is fully mixed with microbubbles generated in the aeration section. Due to the density imbalance between the air-water mixture and the liquid, a vertical upward buoyancy is created, which carries the SS to the water surface. During the floating process, the microbubbles attach to the SS; once reaching the water surface, the SS is supported and maintained there by these bubbles. The SS floating on the water surface is intermittently removed by a chain sludge scraper.

Biochemical System

The MBR system adopts internal (or external) ultrafiltration membrane modules and an online cleaning system. The pretreated wastewater enters the MBR biochemical treatment system. The MBR biochemical reactor consists of a pre-installed denitrification tank and a nitrification tank, both employing a two-stage denitrification and nitrification process.

In the nitrification tank, most organic matter is degraded through the action of highly active aerobic microorganisms; meanwhile, ammonia nitrogen and organic nitrogen are oxidized into nitrates and nitrites. These products are refluxed to the denitrification tank, where they are reduced to nitrogen gas and discharged in an anoxic environment, achieving the goal of nitrogen removal. To improve oxygen utilization efficiency, a high-efficiency internal circulation jet aeration system is adopted, enabling an oxygen utilization rate of up to 35%.

Sludge reflux can increase the sludge concentration in the biochemical reactor to 15 g/L. The microbial community formed through continuous acclimation can also gradually degrade refractory organic matter in the wastewater. The pre-installed denitrification reactor maximizes the utilization of carbohydrates present in the wastewater. The ammonia nitrogen removal rate of the nitrification-denitrification tanks can reach over 90%, with a high pollutant removal load and a sludge concentration of up to 15 g/L.

Keywords:

Messages